This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

WANXIN Hollow Fiber

WANXIN’s Hollow Fibers are the core component of the MBR membranes. Made from high-quality materials, these fibers are designed for superior filtration performance. They effectively filter out contaminants from wastewater, ensuring consistent water quality. Their high durability and resistance to fouling make them a reliable choice for both municipal and industrial wastewater treatment. Choose WANXIN’s Hollow Fibers for an efficient and effective water treatment solution.

WANXIN Hollow Fiber Introduction

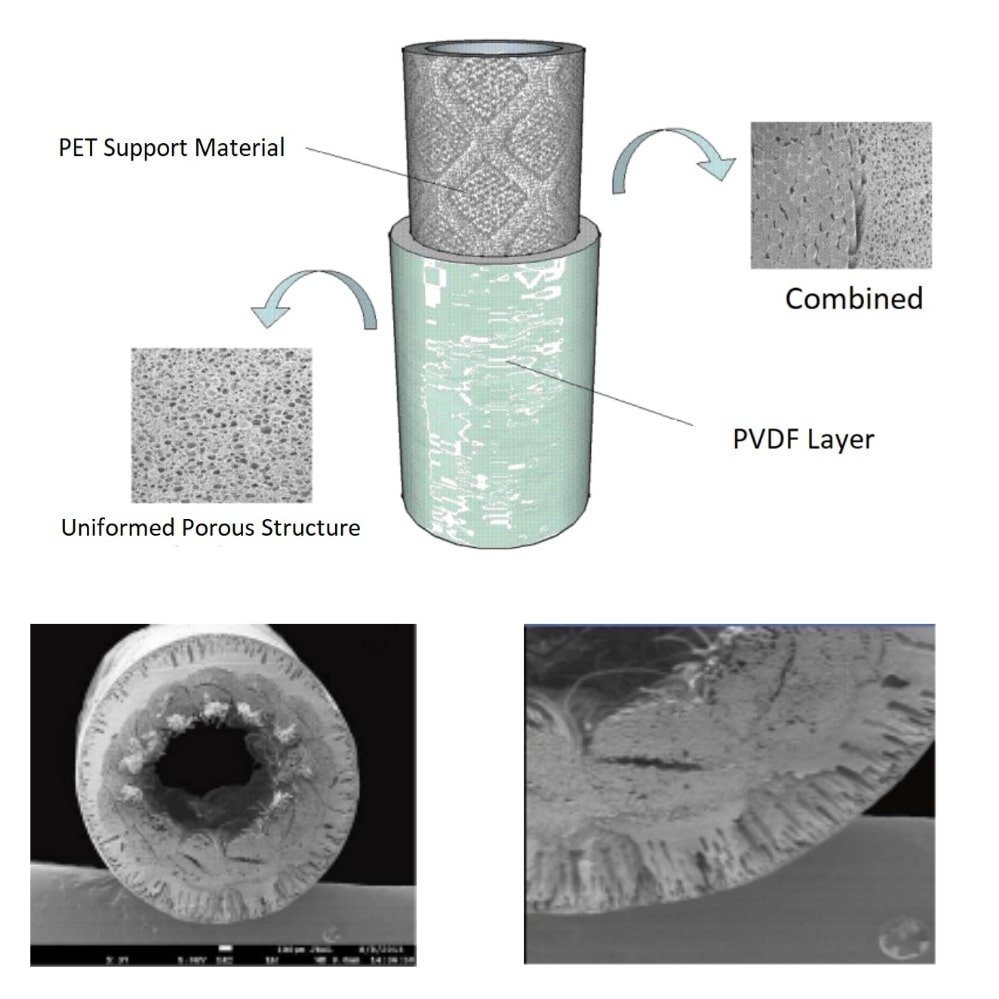

WANXIN hydrophilic PVDF hollow fiber, a product of extensive research and development, is a testament to WANXIN’s commitment to innovation and quality. Crafted using the Thermally Induced Phase Separation (TIPS) process, this fiber boasts superior performance characteristics. Its PET inner-support material enhances its strength, resulting in a tensile strength of ≥20.0MPa and a peeling strength of ≥1.0MPa. Furthermore, its high porosity (≥60%) and large flux (≥200L/m2·h-0.01MPa) ensure efficient and effective filtration.

WANXIN Hollow Fiber Model List

| Model | SPF-440 | SPF-445 | SPF-450 | SPF-460 |

| Type | Reinforced | Reinforced | Reinforced | Reinforced |

| Membrane Material | PVDF + PET | PVDF + PET | PVDF + PET | PVDF + PET |

| Pore Size (μm) | 0.4 | 0.03 | 0.05 | 0.04 |

| Fiber Diameter (mm) | 2.5 ± 0.025 | 2.0 ± 0.025 | 2.5 ± 0.025 | 2.0 ± 0.025 |

| Testing Flux rate (L/m².hr) | ≥40 | ≥40 | ≥40 | ≥40 |

| Design Flux rate (L/m².hr) | 15~20 | 15~20 | 15~20 | 15~20 |

| Raw Material | PVDF (Arkema France) | PVDF (Arkema France) | PVDF (Arkema France) | PVDF (Arkema France) |

| Fiber Tensile (N) | ≥200 | ≥180 | ≥200 | ≥180 |

| Bubble Point (Mpa) | >0.05 | >0.04 | >0.05 | >0.04 |

Exploring WANXIN Hollow Fiber Production

Crafting Excellence

At WANXIN, we utilize advanced machinery and skilled operators to ensure the precise production of our PVDF hollow fibers. Each fiber is crafted with meticulous attention to detail, ensuring the highest quality and performance.

Hands-On Expertise

Our production process involves careful manual oversight, ensuring that each fiber meets our stringent quality standards. This hands-on approach allows us to maintain a high level of control over the production process.

Innovation in Production

We believe in the power of technology to drive innovation. Our state-of-the-art machinery is a testament to this belief. It allows us to produce PVDF hollow fibers with an unmatched level of precision and consistency. This advanced production process ensures that each fiber is crafted to meet our stringent quality standards, delivering a product that is not only reliable but also capable of withstanding the rigorous demands of various water treatment applications. Our commitment to technological innovation is what sets us apart and enables us to provide our customers with high-performance products that lead the industry.

Streamlined Fiber Winding

Our production line is equipped with automated winding machines that ensure each PVDF hollow fiber is wound with precision. This process guarantees uniformity and optimal packing density, enhancing the performance and longevity of our MBR membranes.

Automated Production Line

Automation is key to our production process. It not only increases efficiency but also ensures consistency in the quality of our PVDF hollow fibers. Our automated production line is designed to handle high-volume orders, ensuring we can meet the demands of our customers promptly.

Ready for Dispatch

Our reinforced PVDF hollow fibers are carefully packed and stored on pallets, ready for dispatch. We maintain a large inventory to ensure we can quickly respond to our customer’s needs. Our efficient logistics and supply chain management ensure timely delivery.

Well-stocked Inventory

We maintain a well-stocked inventory of PVDF hollow fibers in our workshop. This allows us to promptly meet the demands of our production schedule and ensure a steady supply of our high-quality MBR membranes to our customers.

Related Products

Explore our range of high-performance MBR membranes. Engineered for superior filtration, efficiency, and durability, our products are trusted worldwide. Let’s get better effluent with WANXIN today!

Our Clients

At WANXIN, we take pride in the strong relationships we’ve built with our clients. Our commitment to quality and service has earned us the trust of numerous businesses worldwide. Here are some moments captured with our valued clients, both in our office and at various exhibitions. These interactions not only strengthen our bonds but also provide us with valuable insights to continually improve our products and services. Join the WANXIN family and experience the difference.

Our Achievements

At WANXIN, we are proud of the recognition we have received for our commitment to innovation, quality, and sustainability in the field of MBR technology. Here are some of our notable achievements:

Patented Technology: Our unique, patented MBR technology underscores our commitment to innovation and industry leadership.

Quality Certification: Our ISO 9001 certification attests to our rigorous quality management and dedication to continuous improvement.

Sustainability Recognition: Our MBR membranes have been recognized for their role in reducing environmental impact and promoting water conservation.

Customer Satisfaction: With a consistent customer satisfaction rate above 95%, we are committed to exceeding customer expectations.

These achievements are a reflection of our team’s hard work and dedication. They motivate us to continue striving for excellence and to keep pushing the boundaries of what is possible in our industry.

Estimated Manufacturing & Shipping Time

We work fast. With the increasing number of customers approaching us, we have no other option but to prioritize speed. Let’s look at the whole process of manufacturing and shipping:

STEP 1

Design and manufacturing time

We design and recommend you the suitable MBR Membrane which fits your projects well. And we manufacturer the MBR in our factory.

STEP 2

Packing & delivering all products time

The staff packs the products on the truck. They take a short time because we have equipments for packing.

STEP 3

Custom Clearance and loading time

The staff load the products into the containers, and once cleared, drivers then transport them to various dispatch points.

STEP 4

Sea and land transportation Time

Once the products arrive at their destination, you will receive an alert. You can plan how to clear and collect your shipped goods.

FAQs About WANXIN MBR Membranes

Wanxin has been wholesaling MBR Membranes for 12 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

Are you a factory or a trading company?

We are the manufacturer and the trading company. We have professional manufacturing teams and a strong oversea sales team.

What's the warranty of your products?

At least 3 years warranty. Meanwhile our team will provide you continuously after-sales services.

How can I become a distributor?

Please contact us through distributor page, we are very willing to discuss distributor program with you.

Where is your factory,Which port for transportation?

What is the delivery time?

Depends on the speed of customs clearance and logistics, but we can guarantee to ship to you within 15 days after deposit received.

Can I get some samples?

We are glad to provide you free samples, just send us a message.

Can I come to China for factory inspection?

Of course, but it is better to wait until the epidemic subsides. Now we support using ZOOM for online factory inspection.

What is the payment terms?

We can accept T/T, L/C, Western Union, Paypal, cryptocurrency and so on. For new customers, we only accept the 30% T/T of the payment, or if you have been with us for years and run into cash flow pressure, we do offer OA credit.

See what our happy clients are talking about us

Let WANXIN boost your business today